The FOX-IQ system can be configured for fully automated alloy testing with data logging and alerts.

Typical Applications:

The FOX-IQ® system is driven by powerful and intuitive software developed specifically for the tube/pipe industry. Features include multilevel access, pass/fail and chemistry analysis, and extensive reporting.

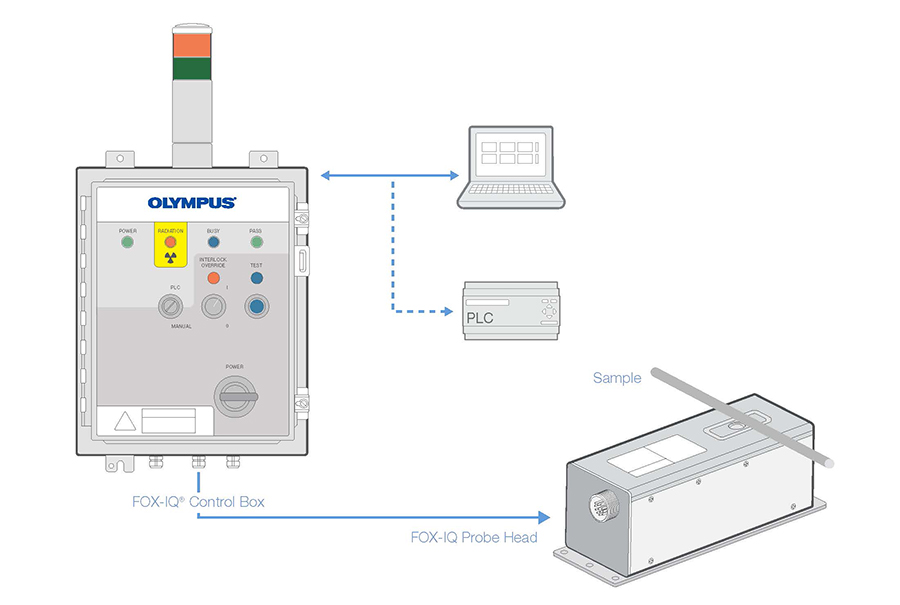

The FOX-IQ in-line analyzer consists of three rugged components:

Probe Head Assembly (PHA):

The PHA contains the X-ray tube, detector, and front-end digital signal processing electronics. The unit can be precalibrated, and its modular design makes it easy to swap out.

Electrical Interface Assembly:

This assembly supports an external sample trigger input and provides a pass/fail indicator signal that can be used to trigger a “kicker” or other line equipment, such as a PLC, to accept or reject the sample based on the analysis result.

User Interface Computer:

The computer runs the PC software that controls the instrument, analyzes the sample, manages the results, and interfaces with customer systems through RS232 or TCP/IP.

| Source | X-ray tube; no radioactive isotopes |

|---|---|

| Detector | Silicon drift detector; <165 eV resolution at 5.95 keV Mn K-alpha line. |

| PC | Windows® XP or Windows 7 operating system. |

| Housing | Anodized aluminum. Sealed from moisture and dust. Shielded from EMI emissions. Weight: Probe Head Assembly: 1.8 kg (4 lb) Electrical Interface: 8 kg (18 lb) |

| Dimensions | Measurement Head (L × W × H): 30.5 cm × 10 cm × 10.5 cm (12 in. × 4 in. × 4.125 in.); Electrical Interface (L × W × H): 40.6 cm × 15.88 cm × 50.8 cm (16 in. x 6.25 in. x 20 in.). |

| Cable Length | Probe Head Assembly to Electrical Interface: up to 30 m (100 ft); Standard Lengths: 15 m. Electrical Interface to PC: dependent on customer requirements. |

| Tube Voltage | 10 kV – 40 kV |

| Current | 80 μA maximum, 10 μA typical |

| Tube Filtering | Up to five (5) filter positions for optimal analysis on 25+ elements |

| Shutter | Automatic shutter for safety and internal standardization |

| Power | AC 110–250 V, 50/60 Hz |

| I/O | The user interface runs on a PC equipped with the Olympus PC software that controls the FOX-IQ; this software analyzes sample spectra, manages results, and interfaces with external devices through RS-485 or TCP/IP. There are dry contacts on all outputs and 24 V start/stop and interlock signals. |

| Data Logging | Up to 12 fields of information per sample including Job #, Work Order, Part #, etc. Auto tracks alarms, pass/fails, and elemental results within a work order or run. Stores >100,000 tests, including results, sample ID, and spectral data, in a binary, tamper-proof format. |

If you have question you can reach us. Just fill up the form below.